US researchers use X-ray to understand the flaws of batteries that use fast-charging technology.

While automotive fuel tanks fill up in minutes, electric car batteries take a long time to charge. To prepare the market to draw more attention to electric vehicles, scientists are striving to develop fast battery charging technology.

Batteries are one of the most important livelihoods of our time and are divided into two main types of use: rechargeable batteries such as mobile phone batteries, laptops, cars, and non-rechargeable batteries since chemical reaction can occur once and in one direction. Only, such as batteries used in a wall clock or in earphones for the hearing impaired.

Although their techniques and uses differ, both types are similar in chemical composition. Scientists have created many batteries with different metals: lead batteries, zinc and carbon batteries, mercury batteries, nickel-cadmium batteries, and in recent decades there has been growing growth in the development of lithium batteries that can be used as a sustainable source of energy in electric vehicles.

Researchers from the Argonne National Laboratory in the United States published a study in the journal Energy and Environmental Sciences, looking for the use of X-rays to identify deficiencies in lithium batteries during operations. Fast shipping.

Daniel Abraham, leader of the research team, said in a statement to Al-Alam: “The speed of charging batteries in general and batteries of electric vehicles in particular is very important, as we seek to reduce the charging time to fifteen minutes or perhaps less,” he said: By seeing the path, distribution, and diffusion of lithium-ions within the battery electrode, we have the opportunity to pinpoint very different reasons for the aging of lithium batteries during fast charging.

The internal structure of the battery consists of four parts: two poles, one positive and one negative, separated by a permeable membrane, which are immersed in electrolyte or electrolyte, which is any substance containing salts ions dissolved in water, and its function is to stimulate the transfer of ions between the poles, that is, conduction of current Electrophoresis.

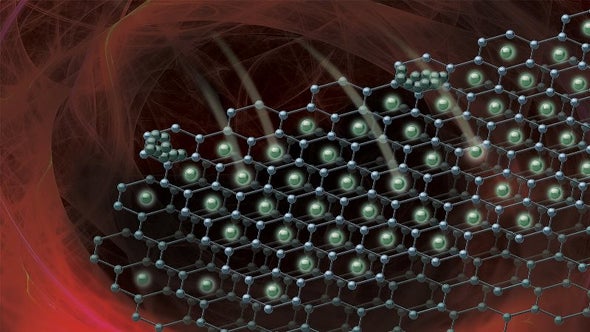

Daniel explained said that “while charging the battery Li + ions move from the positive electrode (lithium) to the negative electrode (graphene), and this process is reflected during the discharge of the battery any use, and added:” The problem of charging technology Rapid is the speed of the transfer of ions between the poles, which leads to consumption during charging and discharging, and we found that most of this consumption is near the membrane separating the poles, unlike the battery terminals.

Daniel explained said that “in the case of slow charge, lithium ions emitted from the anode move gradually to settle between the carbon layers (graphene) stacked on top of each other, in a process called” lithium interference “, but on the other hand, During fast charging, lithium ions are deposited on the graphene surface in the form of metal, in this case called “lithium coating”. “The lithium coating process of the negative electrode prevents the interference of ions between the carbon layers, and therefore the battery efficiency decreases significantly.” , And then the ions cannot travel smoothly between the poles.

The “Daniel” that the lithium metal accumulated on the surface of graphene chemically affect the electrolyte, as it reduces it to become a solid impede the movement of lithium ions, and over time retains the battery less energy inside.

Asked if it was possible to add a chemical to the battery that would prevent the accumulation of lithium on graphene to avoid the coating process, Daniel replied: “It is not possible to add any substance to the battery components, because it will change the properties of chemical electrolysis, and will not replace the coating process. Lithium. “

It is worth mentioning that one way of painting different objects is done in a similar way to the idea of the battery; The paint ions move from the positive electrode to the negative electrode to settle on the body.

To study the movement of lithium ions within fast-charging batteries, the researchers used X-rays, and to see a particular area in the heart of the battery, the researchers used a technique called “X-ray dispersion using energy” to take two-dimensional images of lithium-coated graphene, and discovered that the places where the metal deposits Lithium located near the membrane separating the poles.

“We relied on changing the wavelength of X-rays to define the crystalline structure of graphene, because it is a crystalline material that has a unique arrangement in atoms – its atoms have a hexagonal shape that resembles a honeycomb,” John Uncincense, the second researcher. Instead of changing the angle of projection of rays, he added: “Both methods are used to measure the crystalline structure of graphene according to the Prague equation, but changing the wavelength using energy allows rays to easily penetrate the outer metal of the battery into it.”

“The entry of lithium between graphene layers leads to its expansion,” he said. “Its crystalline reticular structure is inflated to varying degrees. Here comes the role of X-rays scattered by inflation.” “.

“This study is good,” Stanley Whitnam, a professor at Binghamton University in New York, and the founding father of rechargeable lithium batteries, said. “But what we are waiting for is finding ways to make fast-charging technology efficient and safe.” .

Yang Horn, a researcher and energy professor at MIT, said: “The results of the study are very important and are very useful because they offer new insights to meet the challenges of fast-charging technology. Challenges using possible strategies. “

“We don’t have solutions at the moment, but we are currently working on new research that we hope to get fast, efficient and safe battery charging,” said Daniel after Stanley’s comment.

“Our focus in this research is on button batteries, but we are working hard to apply this research to large-scale batteries, such as smart phone batteries and electric car batteries, to study the behavior of lithium,” John Uncense said.

“Daniel” saying: “There are three proposals through which we can reduce the rate of deposition of lithium on graphene (lithium coating), namely: the design of a pole that allows faster diffusion of lithium ions, and the use of graphene allows the introduction of lithium ions between its layers at a rapid pace And finally charge the battery at slightly elevated temperatures, for example at 45 ° C. “

Wonderful blog! Do you have any recommendations for aspiring writers?

I’m hoping to start my own blog soon but I’m a little lost

on everything. Would you suggest starting with a free platform

like WordPress or go for a paid option? There are so many choices out there that

I’m completely overwhelmed .. Any tips? Many thanks!